Sort by:

46 products

46 products

- No special equipment is required and can be used indoors or outdoors.

- Simple operation and easy to use.

- Micro-defects that are difficult to detect with the naked eye can also be highlighted by the bright red color, so it is easy to find scars and avoid mistakes in color inspections.

- There is no restriction on the material, shape and completion status of the object. (Except coated surfaces and plastics)

- In spray form, it is easy to use and easy to carry.

- Safe for use on the most corrosive aluminum and magnesium alloys.

- As long as it is not erased, the inspection results can be saved.

- Inspection can be carried out at room temperature to 80°C.

- Inspection is carried out at -10℃ to 50℃, and the detection sensitivity is 1μm width and 10μm depth.

Product Usage:

It can be used for all metal materials such as iron, non-ferrous, magnetic and non-magnetic, as well as non-metallic materials such as porcelain and glass.

- Cast parts: pinholes, shrinkage cracks

- Forging part: Forging cracks

- Welding parts: cracks, holes, poor joints, penetration defects

- Fatigue phenomena of metal materials: grinding cracks, burning cracks, cutting cracks

- Defect inspection: drums, boilers, pipes, etc.

- Strip Inspection: Strip Inspection of Hot Spot Packaging Materials

Instructions:

The dye penetration flaw detection method is to soak the defective part of the surface of the item to be inspected with a red penetrating liquid, then use a cleaning solution to remove the red penetrating liquid, and then use a white developer to create a capillary image, so that the defective part is soaked in red. The fluid develops color, allowing defects that are invisible to the naked eye to be discovered.

The inspection method specifically refers to the following four basic steps:

Product specifications:

Cleaning fluid:

- Appearance: colorless transparent liquid

- Operating temperature range: 0~60℃

- Content volume: 420ml

- Quantity: 2 cans

Soaking fluid:

- Appearance: red liquid

- Operating temperature range: 0~80℃

- Content volume: 420ml

- Quantity: 1 can

Developer:

- Appearance: White powder coating

- Operating temperature range: 0~50℃

- Content volume: 420ml

- Quantity: 1 can

Originally imported from Japan ICHINEN CHEMICALS Company, Lubricating 303 anti-rust lubricating penetrating agent (penetrating anti-rust lubricating oil/anti-rust lubricant) has anti-rust, lubrication, penetrating and other functions. The 2-purpose nozzle cover design has good rust resistance and permeability, and has low odor. It is no problem to spray upside down.

Product Features:

- Originally imported from Japan's ICHINEN CHEMICALS company, Lubricating 303 anti-rust lubricating penetrating agent has good rust resistance and permeability.

- Lubricating 303 anti-rust lubricating penetrating agent can quickly penetrate the corroded metal surface and exert a lubricating effect on the rusted metal bottom layer.

- Lubricating 303 anti-rust lubricating penetrating agent is sprayed on rusted bolts and nuts, which can penetrate immediately and operate easily.

- Low odor type to reduce unpleasant odors at work

- Unique dual-purpose cap design, no need to replace nozzles

- Penetrating anti-rust lubricant can be sprayed upside down, making it easy to spray even in small areas

Anti-rust and lubrication performance tests under different environments:

| Soak: | Penetration test: 2.36mm/s |

| Anti-rust: | Salt water spray: 48 hours Indoor rust prevention: 6 months |

| lubricating: | Lubrication/reciprocating friction coefficient: 0.112 |

Product Usage:

- Anti-rust, lubrication and penetration of automobiles, motorcycles, bicycles and mechanical parts

internal volume:

- 420ml

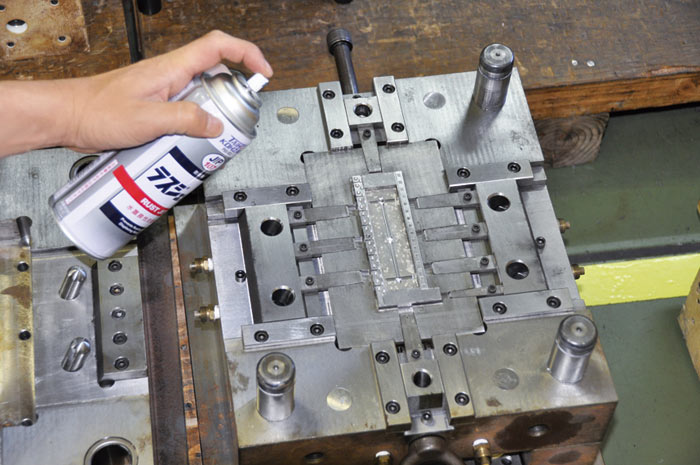

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml

- Original imported from ICHINEN CHEMICALS CO., LTD., JIP25240 gas pipeline foam leak detector, gas/cold coal leak detector

- Spray leak detector can quickly detect air leaks with just one spray

- If gas leaks out, foam will be generated as soon as it is sprayed. It is easy to detect small air leaks and leaks. Leak detection

- Reacts to tiny gases and bubbles at any time

- Foaming leak test (JIS-Z2329): For 30 micron holes, foaming with a differential pressure of 4~5x103Pa

- The leak detection agent is a colorless and transparent liquid, which is non-flammable and will not cause danger due to chemical reactions.

- The leak detector will not affect the environment or human skin health; paint, rubber, and plastic surfaces will not be affected either.

- Suitable for oil pipelines, gas, refrigerant, pressure pipelines, welded joints, clutch compressors, automobile and motorcycle tires, braking systems, etc.

Scope of application:

- The discovery of gas leakage at the joints of various gas equipment piping systems

- Detection of refrigerant leakage at piping joints of air-conditioning refrigerators and other machines

- Detection of air leakage at piping joints in air compressors, pressure vessels, air conditioners, etc.

- Searching for leaks in tires and braking systems of cars, motorcycles and trucks

- Household gas, liquefied petroleum gas leakage search

Product specifications:

- Contents: 351g

Different from the general soap bubble test:

- Our company's leak detection agent is a high-pressure water-soluble liquid, which is a mist spray that spreads evenly and has a large surface tension. When the pipeline leaks, it will immediately generate bubbles, making it easy to find the leak. Compared with ordinary soap bubbles, it is easier to detect, improves work efficiency and saves time.

JIP179 metal blackening agent is a high-efficiency blackening colorant, specially designed for blackening various metal products or materials, such as iron, aluminum, stainless steel, copper and plastic. Originally imported from Japan's ICHINEN CHEMICALS CO., LTD., the black dye combines excellent performance and multi-functional features to ensure that your products achieve the best visual effects and protection.

Features:

Fast drying speed: JIP179 metal blackening agent has an extremely fast drying speed and maintains excellent adhesion, ensuring that the blackening effect is immediate.

Water Resistance: JIP179 metal black dye has excellent water resistance, ensuring your products maintain a long-lasting black coloration and are protected from moisture damage, even in humid environments.

Oil resistance: JIP179 metal blackening agent is not easily soluble in oil films and is suitable for applications that require contact with grease.

Wear resistance: This black dye shows excellent wear resistance and is not easily abraded or scratched. Even if metal collides with metal, it is not easy to peel off.

Ultra-thin coating: JIP179 metal blackening agent only forms an extremely thin film, maintaining the texture of the original material and does not affect the size or texture of the product.

Anti-rust function: This black dye also has anti-rust properties, ensuring that your metal products remain intact for a long time and extend their service life.

Low-gloss dark black: JIP179 metal black dye presents a low-gloss dark black, bringing a unique visual effect to your products, adding a sense of luxury and beauty.

In short, JIP179 metal blackening agent is a high-quality blackening product suitable for many application fields. It is an indispensable choice whether in industrial production, making exquisite handicrafts, or protecting metal surfaces from environmental influences. It brings a long-lasting black effect to your products while providing superior protection and visual beauty.

Be applicable:

- Black coating of iron, stainless steel, aluminum, copper and other metals

- Black coating of polyacetal resin (Polyacetal plastic steel) and ABS resin

- Partial repair of black products or small parts

Product performance:

- Dry to touch: 2 - 3 minutes

- Hardening and drying: about 20 minutes

- Heat-resistant temperature: 15℃ (continuous use 100℃)

- Coating area: 1.5m²

- Operating temperature range: normal temperature

Instructions:

- Before painting plastic, please test it to see if the plastic will be corroded.

- Thoroughly remove grease and clean the material to be dyed black before use

- Please shake well before spraying. When spraying, keep it about 20-30cm away from the object to be coated, and spray evenly. Please divide it into 2-3 times and spray it in batches. Do not spray it very thickly at one time to obtain the best blackening effect.

- The spray will dry within a few minutes, please proceed to the next step after it is fully dry.

Product specifications:

- 420ml

Origin:

- Made in Japan

※Notice:

JIP179 metal blackening agent is an ultra-fine particle blackening colorant, not a black spray paint~

It is flammable, please use it outdoors or in a place with good air circulation.

Please test whether the rubber spray will be corroded first.

Please stay away from fire sources or high temperature places.

JIP189 chlorine-free screw cutting spray, environmentally friendly chlorine-free thread cutting lubricant, imported from Japan, environmentally friendly chlorine-free material, suitable for thread tapping cutting lubrication, no need to worry about corrosion of materials or tools.

feature of product:

- Environmentally friendly chlorine-free thread cutting lubricant that does not use chlorinated paraffin and other raw materials, so there is no need to worry about the production of dioxin

- Based on mineral oil and using non-reactive additives, there is no need to worry about corrosion of materials or tools.

- No odor caused by sulfur additives

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

Used for thread cutting, drilling, reaming, broaching of steel, various metals and non-metals, and lubrication during cutting

Performance/Characteristics:

Fusion load: 2120N

Steel plate corrosion: 1a (100℃x1hr)

Kinematic viscosity (40℃): 44.7cSt

Operating temperature range: below 100℃

capacity:

420ml

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml

ICHINEN CHEMICALS CO., LTD. JIP130 ultra-durable rust-proof galvanized paint is a spray product made of single-liquid concentrated zinc and epoxy resin paint, which is anti-rust and super durable.

Concentrated galvanizing anti-rust agent anti-rust paint uses ultra-fine powdered metallic zinc to prevent iron corrosion in an electrically scientific and chemical manner. At the same time, a gradually stable insoluble protective film will be formed on the surface of the zinc powder, thereby increasing the anti-corrosion performance, even if the metal surface has been If there are scratches, you can also use this product to prevent rust and corrosion.

feature of product:

- Japan's ultra-durable anti-rust galvanized paint (concentrated galvanized anti-rust agent anti-rust paint, cold galvanized agent anti-rust spray paint)

- Super durable anti-rust galvanized paint, galvanized anti-rust paint, anti-rust and anti-corrosion

- Concentrated galvanizing anti-rust agent and anti-rust paint are easily adsorbed on the base metal

- Can be used to protect metal surfaces even if they are scratched or damaged

- Cold galvanizing agent anti-rust spray paint salt spray anti-rust test up to 500 hours, good anti-rust effect

- After the Japanese ultra-durable anti-rust galvanized coating is applied, any paint or coating can be applied. However, "phthalic acid" paint may cause delamination, so please do not use it.

Product specifications:

- Capacity 450g

- Color: silver gray

Performance/Characteristics::

- Metal powder in dry coating: 84% or more

- Soaked in tap water: more than 1 year

- Outdoor rust prevention: more than 2 years

- Drying time: Touch dry: About 5 minutes based on 20 degrees C / Curing and drying: 7 hours

- Salt spray anti-rust test: more than 500 hours (generally about 250 hours on the market)

- Film thickness: 15~25μm (this is the basis for one coating, and may vary depending on coating speed, distance, etc.)

- Coating area: 0.4~0.6m2 (calculated based on film thickness 30-40μm, there will be differences depending on the coating)

use:

- Cold galvanizing agent anti-rust spray paint is used for galvanizing repairs, primer anti-rust for welding parts, and anti-corrosion for steel pipes

- Suitable for oil drilling equipment, chemical industry, ship power equipment, car body manufacturing, storage tanks, bridges, harbor mechanical facilities, terminal equipment, railway equipment, buildings, vehicles, agricultural machinery, chemical instrumentation, etc.

Operating temperature range:

- Heat resistance ( short time ) : 180 ℃

- Heat resistance ( long time ) : below 150 ℃

JIP659 oil leakage detection fluid can easily detect oil leakage. It only needs to be applied externally and will not stain the inside.

feature of product:

- JIP659 Oil Leak Check Fluid

- Oil leaks can be easily detected through the white coating film

- It can suck out liquids and perform inspections without pressurization.

- Only the outside is coated and the inside will not be stained

- Can be cleaned by washing after inspection

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Detect oil leakage from welded parts and joints of various oil piping (also applicable to rubber pipes)

- Found oil leakage in welded parts and joint parts of various oil tanks

- Detect oil leakage from the fuel tank joints and brake hose piping parts of automobiles, etc.

Performance/Characteristics:

- Appearance (after drying): white powder coating

- Operating temperature range: 0-50℃

capacity:

- 150ml

ICHINEN CHEMICALS CO., LTD. JIP188 grease for food machinery. The lubricant raw materials comply with the NSF H1 specification of the U.S. Food and Drug Administration (FDA) and have excellent water resistance, oxidation stability, and mechanical stability. Grease spray for food machinery using white grease spray.

feature of product:

- JIP188 Grease for food machinery. Grease spray for food machinery. White grease spray with excellent water resistance, oxidation stability, and mechanical stability.

- Lubricant for food machinery is used in parts that may have incidental contact with food.

- Food-grade lubricating oil has excellent oxidation stability and long-lasting lubrication effect.

use:

- Used for lubrication of chains or hinged parts of food machinery

- Filling machinery for fish and meat processing machinery and alcoholic beverages

Performance/Characteristics:

| Pilot projects | experiment method | test results | ||

| consistency | JIS K 2220 | 365 | ||

| Dropping Point | JIS K 2220 | 217℃ | ||

| oil separation | JIS K 2220 | 10.2wt% | ||

| Low temperature torque test | JIS K 2220 | 20℃ | Starting torque 6.7N.cm | |

| Rotary torque 4.3N.cm | ||||

| 20℃ | Starting torque 20.N.cm | |||

| Rotary torque 11.8N.cm | ||||

| Four-ball shell test | ASTM D 2596 | Maximum non-sticking | 1236N | |

| Melted with load | 3090N | |||

| Load wear index | 578N | |||

| Soda Four Ball Test | JIS K 2519 | Qualified limit load | 0.441Mpa | |

| Average wear marks | 0.79mm | |||

safety:

| Pilot projects | test results | |

| Material test | lead | Below 1ppm |

| cadmium | Below 1ppm | |

| Dissolution test | heavy metal | 1ppm or less (as Pb) |

| Potassium permanganate consumption | 0.5ppm or less | |

Product specifications:

- Content volume 300ml

NSF H1 certification number:

- NO.144729

What is NSF?

NSF (National Sanitation Foundation) is a non-profit third-party organization in the United States. It adheres to the previous USDA (United States Department of Agriculture) certification process and certifies the safety of chemicals used at food processing sites (H1 and 3H are also included in its certification).

- NSF H1: H1 is a benchmark for lubricants used in mechanical parts that may occasionally come into contact with food.

Lubricants should not come into direct contact with food, but safety will not be affected if mixed with food.

Instructions:

● Please shake well before use.

● Keep a spraying distance of 5-15cm from the object being sprayed. If the spray reaches a location other than the object, please wipe it clean with a cloth as soon as possible.

※Notice:

● JIP188 grease for food machinery is flammable, please keep away from fire sources or high temperatures.

● Do not use it upside down.

● It will form stains on clothes .

ICHINEN CHEMICALS CO., LTD. JIP130 ultra-durable rust-proof galvanized paint is a spray product made of single-liquid concentrated zinc and epoxy resin paint, which is anti-rust and super durable.

Concentrated galvanizing anti-rust agent anti-rust paint uses ultra-fine powdered metallic zinc to prevent iron corrosion in an electrically scientific and chemical manner. At the same time, a gradually stable insoluble protective film will be formed on the surface of the zinc powder, thereby increasing the anti-corrosion performance, even if the metal surface has been If there are scratches, you can also use this product to prevent rust and corrosion.

feature of product:

- Japan's ultra-durable anti-rust galvanized paint (concentrated galvanized anti-rust agent anti-rust paint, cold galvanized agent anti-rust spray paint)

- Super durable anti-rust galvanized paint, galvanized anti-rust paint, anti-rust and anti-corrosion

- Concentrated galvanizing anti-rust agent and anti-rust paint are easily adsorbed on the base metal

- Can be used to protect metal surfaces even if they are scratched or damaged

- Cold galvanizing agent anti-rust spray paint salt spray anti-rust test up to 500 hours, good anti-rust effect

- After the Japanese ultra-durable anti-rust galvanized coating is applied, any paint or coating can be applied. However, "phthalic acid" paint may cause delamination, so please do not use it.

Product specifications:

- Capacity 450g

- Color: silver gray

Performance/Characteristics::

- Metal powder in dry coating: 84% or more

- Soaked in tap water: more than 1 year

- Outdoor rust prevention: more than 2 years

- Drying time: Touch dry: About 5 minutes based on 20 degrees C / Curing and drying: 7 hours

- Salt spray anti-rust test: more than 500 hours (generally about 250 hours on the market)

- Film thickness: 15~25μm (this is the basis for one coating, and may vary depending on coating speed, distance, etc.)

- Coating area: 0.4~0.6m2 (calculated based on film thickness 30-40μm, there will be differences depending on the coating)

use:

- Cold galvanizing agent anti-rust spray paint is used for galvanizing repairs, primer anti-rust for welding parts, and anti-corrosion for steel pipes

- Suitable for oil drilling equipment, chemical industry, ship power equipment, car body manufacturing, storage tanks, bridges, harbor mechanical facilities, terminal equipment, railway equipment, buildings, vehicles, agricultural machinery, chemical instrumentation, etc.

Operating temperature range:

- Heat resistance ( short time ) : 180 ℃

- Heat resistance ( long time ) : below 150 ℃

- No special equipment is required and can be used indoors or outdoors.

- Simple operation and easy to use.

- Micro-defects that are difficult to detect with the naked eye can also be highlighted by the bright red color, so it is easy to find scars and avoid mistakes in color inspections.

- There is no restriction on the material, shape and completion status of the object. (Except coated surfaces and plastics)

- In spray form, it is easy to use and easy to carry.

- Safe for use on the most corrosive aluminum and magnesium alloys.

- As long as it is not erased, the inspection results can be saved.

- Inspection can be carried out at room temperature to 80°C.

- Inspection is carried out at -10℃ to 50℃, and the detection sensitivity is 1μm width and 10μm depth.

Product Usage:

It can be used for all metal materials such as iron, non-ferrous, magnetic and non-magnetic, as well as non-metallic materials such as porcelain and glass.

- Cast parts: pinholes, shrinkage cracks

- Forging part: Forging cracks

- Welding parts: cracks, holes, poor joints, penetration defects

- Fatigue phenomena of metal materials: grinding cracks, burning cracks, cutting cracks

- Defect inspection: drums, boilers, pipes, etc.

- Strip Inspection: Strip Inspection of Hot Spot Packaging Materials

Instructions:

The dye penetration flaw detection method is to soak the defective part of the surface of the item to be inspected with a red penetrating liquid, then use a cleaning solution to remove the red penetrating liquid, and then use a white developer to create a capillary image, so that the defective part is soaked in red. The fluid develops color, allowing defects that are invisible to the naked eye to be discovered.

The inspection method specifically refers to the following four basic steps:

Product specifications:

- Appearance: white powdery coating

- Operating temperature range: 0~50℃

- Content volume: 420ml

- No special equipment is required and can be used indoors or outdoors.

- Simple operation and easy to use.

- Micro-defects that are difficult to detect with the naked eye can also be highlighted by the bright red color, so it is easy to find scars and avoid mistakes in color inspections.

- There is no restriction on the material, shape and completion status of the object. (Except coated surfaces and plastics)

- In spray form, it is easy to use and easy to carry.

- Safe for use on the most corrosive aluminum and magnesium alloys.

- As long as it is not erased, the inspection results can be saved.

- Inspection can be carried out at room temperature to 80°C.

- Inspection is carried out at -10℃ to 50℃, and the detection sensitivity is 1μm width and 10μm depth.

Product Usage:

It can be used for all metal materials such as iron, non-ferrous, magnetic and non-magnetic, as well as non-metallic materials such as porcelain and glass.

- Cast parts: pinholes, shrinkage cracks

- Forging part: Forging cracks

- Welding parts: cracks, holes, poor joints, penetration defects

- Fatigue phenomena of metal materials: grinding cracks, burning cracks, cutting cracks

- Defect inspection: drums, boilers, pipes, etc.

- Strip Inspection: Strip Inspection of Hot Spot Packaging Materials

Instructions:

The dye penetration flaw detection method is to soak the defective part of the surface of the item to be inspected with a red penetrating liquid, then use a cleaning solution to remove the red penetrating liquid, and then use a white developer to create a capillary image, so that the defective part is soaked in red. The fluid develops color, allowing defects that are invisible to the naked eye to be discovered.

The inspection method specifically refers to the following four basic steps:

Product specifications:

- Appearance: colorless transparent liquid

- Operating temperature range: 0~60℃

- Content volume: 420ml

- Japan's ICHINEN CHEMICALS company originally imported NX86 heat-resistant black heat-resistant paint heat-resistant paint, heat-resistant temperature 600 o C

- Heat-resistant black heat-resistant paint has less discoloration and will not peel off due to the thermal shock of cold water even at 600 ° C.

- High temperature resistant coatings can prevent corrosion such as salt damage

- Heat-resistant black heat-resistant paint When the heat-resistant paint film dries, it is heated to form a conformable hardened film.

- Imported from Japan

Product Usage:

- Used for steam pipes and other parts that require heat resistance

- Used in chimneys, boilers and other equipment

- Silencer box for generators, etc.

- Suitable for spraying of automobile and motorcycle exhaust pipes

Performance/Characteristics:

| Dry to the touch | 15~20 minutes |

| Harden and dry | Varies depending on heating conditions |

| heat resistance temperature | 600 ° C |

| Coating area | 0.6 ~ 0.7m 2 |

internal volume:

- 300ml

Remark:

- High-temperature resistant paint/heat-resistant paint generally refers to special functional paint that can withstand temperatures above 200 ° C for a long time and maintain certain physical and chemical properties so that the protected object can function normally in a high-temperature environment.

Originally imported from Japan's ICHINEN CHEMICALS company, this quick-drying brake and parts cleaner is a powerful metal degreasing cleaner that can quickly and safely clean disc brakes, drum brakes, brake calipers and other brake parts. It has excellent cleaning properties. Effect. Brake cleaner (brake disc cleaner) can be sprayed upside down. It has low toxicity and is not corrosive to metal. It can be safely used on brake pads, disc brake pads and brake drums. It can quickly clean metal parts, metal molds, Oil stains, grease and dirt on precision machinery, etc.

feature of product:

- Quick drying, excellent cleaning effect, low toxicity chemical detergent

- Can quickly remove oil stains, grease and dirt from metal parts, metal molds, precision machines, etc.

- Remove grease and dirt from gears, bearings, etc.

- Not corrosive to metals

Be applicable:

- Clean grease and dirt from metal parts, metal molds, tools, etc.

- Remove grease dirt from gearboxes, bearings, etc.

- Remove oil stains from hydraulic machines, cylinders, etc., remove oil stains with strips, and clean precision machines

- Clean brake pads (disc and drum), wheel cylinders, clutch discs, pressure plates, springs and other metal parts

Content volume: 500ml

Origin: Japan

Originally imported from Japan's ICHINEN CHEMICALS company, the brake disc cleaner is a quick-drying, powerful oil-removing cleaning agent with excellent cleaning effects. Brake disc cleaner can be sprayed upside down. It is a chemical detergent with low toxicity and is not corrosive to metal. It can quickly remove oil stains, anti-rust oil and cutting oil from metal parts, metal molds, precision machines, etc.

feature of product:

- Quick drying, excellent cleaning effect, low toxicity chemical detergent

- Can quickly remove oil stains, anti-rust oil and cutting oil from metal parts, metal molds, precision machines, etc.

- Remove grease stains from gears, bearings, etc.

- Not corrosive to metals

- Little impact on various resins and rubbers

Be applicable:

- Clean anti-rust oil and cutting oil on metal parts, metal molds, tools, etc.

- Remove grease stains from gears, bearings, etc.

- Remove oil stains from hydraulic machines, cylinders, etc., remove oil stains with strips, and clean precision machines

- Clean around the brakes of cars, forklifts, etc.

Product specifications: 840ml

Origin: Made in Japan

NX60 brake cleaner is a powerful degreasing cleaner with the best decontamination and cleaning power among spray cleaners. It is suitable for cleaning oil stains on metal parts, pipes, motors, chains, and brakes.

feature of product:

- The best detergent power among spray cleaners

- Not quick-drying, so it can penetrate oil stains and clean even small amounts

- Because the cleaning power is too strong, it is not suitable for cleaning resin, rubber products, and painted surfaces.

- It has good miscibility with glycol brake fluid, will not separate, and has good cleaning effect.

- Can also remove oil-based ink from marker pens

Scope of application:

- Clean oil stains from metal parts

- Remove oil stains from pipes, motors, etc.

- Clean the areas around the brakes of cars, forklifts, etc.

- Remove marking paint and marker pen oil-based ink from metal surfaces

- Remove oil from chains

capacity:

500ml

ICHINEN CHEMICALS CO.,LTD. NX5000 engine carbon cleaner is a high-efficiency foam cleaner used to clean carburetors, combustion chambers, exhaust valves, throttle valves, and piston tops due to incomplete combustion. Carbon deposits and dirt caused by this.

feature of product:

- Foaming high-efficiency dissolving technology cleans carbon deposits and dirt caused by incomplete combustion on the carburetor, combustion chamber, exhaust valve, throttle valve, and piston top

- Disassembly and washable, easy to use

- Prevent fuel system corrosion and effectively remove carbon deposits

- Reduce fuel consumption

- Improve vehicle starting and driving performance

- Cleaning every 5,000 kilometers ensures the engine works smoother

use:

- Does not corrode parts, making the engine easy to start, accelerate smoothly, increase horsepower, and save fuel

- Reduce exhaust emissions and can be applied to gasoline engine vehicles

internal volume:

- 240ml

Notice:

It is flammable, please keep away from fire or high temperature.

Not for use on 2-stroke engines and diesel vehicles (can be used for disassembly and cleaning) .

Depending on the vehicle model, use may be prohibited by the vehicle manufacturer, please follow the vehicle manufacturer's instructions .

ICHINEN CHEMICALS CO., LTD. JIP117 electronic parts cleaner, quick-drying type, has little effect on various resins and rubbers, and is super effective at degreasing and cleaning electronic parts.

feature of product:

- Japan's original JIP117 electronic parts cleaner can clean electronic parts wiring base plates.

- Electronic component cleaning agent can clean and remove carbon and grease from electronic contacts.

- Electronic parts cleaners are chemical cleaners with low toxicity.

- Electronic contact cleaner, quick-drying type, has minimal impact on various resins and rubbers.

- Suitable for cleaning electric lamps, electronic machinery, precision machinery, general machinery and parts .

use:

- Clean various machine wiring boards

- Clean the relay contacts of various machines and restore contact functions

- Clean pin jacks, volume connectors, etc.

- Degreasing and cleaning metal parts, etc.

Performance/Characteristics:

- Operating temperature range: normal temperature

Product specifications:

- Content volume: 420ml

Instructions:

- When spraying, keep the distance from the target object about 20 cm

- Before applying power, wipe the parts with a cloth to dry and make sure the air is dry

- Exhaust the solvent vapor and then turn on the electricity. It can also be used for contact cleaning. It has little effect on rubber and plastic, but please do not overdose.

※Notice:

JIP117 electronic parts cleaner is flammable, please do not use it when the power is on.

Do not use too much electronic parts cleaner on rubber, plastic, or painted surfaces.

This product cannot be used with certain materials, such as PS, PC and PPO.

Please stay away from fire sources or high temperature places.

Cutting lubricant, also known as cutting oil, cutting fluid, or lubricant, is an auxiliary effect of lubrication during the cutting process. Japan's original JIP111 stainless steel cutting lubricant can speed up the cutting speed and improve work efficiency for difficult-to-cut stainless steel and aluminum materials.

Product Features:

- JIP111 cutting lubricant for stainless steel, the role of chlorine-based extreme pressure additives can prevent welding

- Effective for difficult-to-cut materials, such as stainless steel, aluminum, etc.

- Speed up cutting speed and improve work efficiency

- Reduce cutting edge wear and extend tool life

- Helps smooth chip removal and prevents burrs, curls, chips and bites

- Beautify the finished surface and improve dimensional accuracy

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

Used for tapping, thread cutting, drilling, reaming, broaching and other difficult-to-cut materials such as stainless steel, aluminum, copper and titanium alloys to lubricate during the cutting process

Performance/Characteristics:

Fusion load: 4903N

Steel plate corrosion: 1a (100℃x1hr)

Kinematic viscosity (40℃): 36cSt

Operating temperature range: below 100℃

capacity:

330ml

JIP189 chlorine-free screw cutting spray, environmentally friendly chlorine-free thread cutting lubricant, imported from Japan, environmentally friendly chlorine-free material, suitable for thread tapping cutting lubrication, no need to worry about corrosion of materials or tools.

feature of product:

- Environmentally friendly chlorine-free thread cutting lubricant that does not use chlorinated paraffin and other raw materials, so there is no need to worry about the production of dioxin

- Based on mineral oil and using non-reactive additives, there is no need to worry about corrosion of materials or tools.

- No odor caused by sulfur additives

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

Used for thread cutting, drilling, reaming, broaching of steel, various metals and non-metals, and lubrication during cutting

Performance/Characteristics:

Fusion load: 2120N

Steel plate corrosion: 1a (100℃x1hr)

Kinematic viscosity (40℃): 44.7cSt

Operating temperature range: below 100℃

capacity:

420ml

ICHINEN CHEMICALS CO., LTD. JIP127 lubricant for food machinery. The lubricant itself is food. The raw materials use specifications required by the U.S. Food and Drug Administration (FDA). Lubricants that are allowed to come into direct contact with food are not allowed. NSF certified food grade lubricant. Suitable for lubrication and rust prevention of food machinery, food cutting knives, agricultural cutting knives, etc. to prevent food from adhering to the knives (for business use).

feature of product:

- Japanese original JIP127 lubricant for food machinery. Food-grade lubricating grease itself is food. It is a food-grade lubricating grease produced on a professional and hygienic management edible oil production line.

- The safety index is acute toxicity LD 50 =15g/kg, which is essentially non-toxic.

- Food-grade lubricants have characteristics such as fluidity, permeability, digestion and absorption that ordinary vegetable oils do not have.

- Lubricants for food machinery are composed of medium-chain fatty acid triglycerides made of high-purity vegetable fatty acids, so they have excellent oxidation stability (preservability) and long-lasting lubricating effects.

use:

- Lubrication of machinery used in food production

- Lubrication of knives used for cutting food

Performance/Characteristics:

| Lubricity | dynamic friction coefficient | Vibrator type friction coefficient: 0.17 |

| Load resistance | Soda style 200rpm:0.55Mpa | |

| Chloride stability | 97.8±2℃ | More than 300 hours |

| Temperature characteristics | Operating temperature range | -5 o C~200℃ |

| flashpoint | 240℃ |

Biological and biochemical properties:

| smell | Tasteless |

| Digestive | Even without bile and pancreatic juice, water can be broken down and absorbed |

| metabolism | Almost oxidized into energy, a small amount will be stored as fat tissue |

| coliforms | Negative |

Product specifications:

- Content volume 420ml

NSF H1.3H certification number:

- No.144730

What is NSF?

NSF (National Sanitation Foundation) is a non-profit third-party organization in the United States. It adheres to the previous USDA (United States Department of Agriculture) certification process and certifies the safety of chemicals used at food processing sites (H1 and 3H are also included in its certification).

- NSF H1: H1 is a benchmark for lubricants used in mechanical parts that may occasionally come into contact with food.

Lubricants should not come into direct contact with food, but safety will not be affected if mixed with food. - NSF 3H: 3H is a standard for release agents (release agents) used to effectively separate food from hard surfaces during food processing.

It is used for processing barbecued food, ice cream, cakes, butter and other utensils that come into direct contact with food. It uses raw materials such as cooking oil that are safe to be eaten.

Instructions:

- Please shake well before use.

- Keep a spraying distance of 15-20cm from the object being sprayed, and use the nozzle in narrow or out-of-reach places.

※Notice:

- JIP127 lubricant for food machinery is flammable, please keep away from fire sources or high temperatures.

- Do not use upside down.

- It will form stains on clothes.

NX22 molybdenum disulfide lubricant is NX22 molybdenum disulfide lubricant. Molybdenum disulfide has good lubricity, pressure resistance and wear resistance, and is used in equipment operating under high speed, heavy load, high temperature and other working conditions.

Product Features:

- High lubrication performance can be maintained from low temperature to high temperature (-30 - 400℃)

- High load resistance and extremely low friction coefficient

- Forms a moist molybdenum disulfide film, which is chemically stable and can be used in places immersed in organic solutions or water.

- Compatible with general lubricants to improve lubrication performance

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Used to prevent working machinery, construction machinery, and automobile-grade crushing moving and rotating parts from burning, seizing, wear, and squeaking.

- Used to prevent malfunctions, burning and squeaking of screws when assembling machinery.

Performance/Characteristics:

- Fusion load: 2452N

- Heat resistance: 400℃

- Vibrator friction coefficient: 0.10

- Operating temperature range: -30 ~ 400℃

capacity:

300ml

JIP107 water-displacing anti-rust agent/anti-rust oil imported from Japan can effectively prevent any metal from rusting. It will not corrode the metal surface or cause discoloration. It can also prevent rust caused by fingerprints.

feature of product:

- Water displacing, suitable for preventing rust on any metal and will not corrode metal surfaces or cause discoloration

- Does not interfere with electrical contacts and has excellent protection for electrical equipment

- Prevents corrosion caused by seawater adhesion or working on the sea surface, and prevents rust caused by fingerprints.

- The skin of RUST JET can be easily removed using a topical remover.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Used for rust prevention of all metal products, precision machinery, jigs, plates, etc.

- Prevent complex cables such as electrical equipment, batteries, communication equipment, and motors from rusting

- Anti-rust treatment for metal molds

Performance/Characteristics:

- Salt water spray: more than 120 hours

- Indoor rust prevention: more than 24 months

- Outdoor rust prevention: not available

- Film thickness: 2~3µm

- Operating temperature range: -10~120℃

capacity:

420ml

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml

ICHINEN CHEMICALS CO.,LTD. JIP694 super powerful rust remover is a metal rust remover and rust removal water . It is suitable for metal rust removal. It has good rust removal effect and can extend the use of components. longevity and ease of use.

feature of product:

- After soaking rusty metal or metal parts in JIP694 super powerful rust remover for a few minutes, the rust on the surface will fall off.

- Rust can be easily removed by just soaking, excellent rust removal effect

Product Usage:

- Suitable for rust removal on metals, not suitable for non-metallic materials and surfaces

- Suitable for removing oxidative films formed by concrete, lime, calcium deposits, etc. attached to metal surfaces

Instructions:

- After spraying evenly on the rusted area, let it sit for a few minutes.

- Wipe with a rag to remove rust.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, be sure to perform rust prevention treatment. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

How to deal with severe rust:

- Using a tool such as a steel brush, pour the rust remover onto the container, and then use the brush to brush the rusted surface.

- After applying the rust remover, it is necessary to allow the rust remover to take effect. The leaving time should not exceed 10 minutes, otherwise the rust removal reaction will cause normal parts to be corroded as well.

- Use a steel brush to remove rust spots on the surface.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, rust prevention treatment must be performed. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

Product specifications:

- Capacity 500ml

ICHINEN CHEMICALS CO., LTD. JIP117 electronic parts cleaner, quick-drying type, has little effect on various resins and rubbers, and is super effective at degreasing and cleaning electronic parts.

feature of product:

- Japan's original JIP117 electronic parts cleaner can clean electronic parts wiring base plates.

- Electronic component cleaning agent can clean and remove carbon and grease from electronic contacts.

- Electronic parts cleaners are chemical cleaners with low toxicity.

- Electronic contact cleaner, quick-drying type, has minimal impact on various resins and rubbers.

- Suitable for cleaning electric lamps, electronic machinery, precision machinery, general machinery and parts .

use:

- Clean various machine wiring boards

- Clean the relay contacts of various machines and restore contact functions

- Clean pin jacks, volume connectors, etc.

- Degreasing and cleaning metal parts, etc.

Performance/Characteristics:

- Operating temperature range: normal temperature

Product specifications:

- Content volume: 420ml

Instructions:

- When spraying, keep the distance from the target object about 20 cm

- Before applying power, wipe the parts with a cloth to dry and make sure the air is dry

- Exhaust the solvent vapor and then turn on the electricity. It can also be used for contact cleaning. It has little effect on rubber and plastic, but please do not overdose.

※Notice:

JIP117 electronic parts cleaner is flammable, please do not use it when the power is on.

Do not use too much electronic parts cleaner on rubber, plastic, or painted surfaces.

This product cannot be used with certain materials, such as PS, PC and PPO.

Please stay away from fire sources or high temperature places.

Lubricating 303 anti-rust lubricating penetrating agent (DJ-0303-42024)

Lubricating 303 anti-rust lubricating penetrating agent (DJ-0303-42024)

Originally imported from Japan ICHINEN CHEMICALS Company, Lubricating 303 anti-rust lubricating penetrating agent (penetrating anti-rust lubricating oil/anti-rust lubricant) has anti-rust, lubrication, penetrating and other functions. The 2-purpose nozzle cover design has good rust resistance and permeability, and has low odor. It is no problem to spray upside down.

Product Features:

- Originally imported from Japan's ICHINEN CHEMICALS company, Lubricating 303 anti-rust lubricating penetrating agent has good rust resistance and permeability.

- Lubricating 303 anti-rust lubricating penetrating agent can quickly penetrate the corroded metal surface and exert a lubricating effect on the rusted metal bottom layer.

- Lubricating 303 anti-rust lubricating penetrating agent is sprayed on rusted bolts and nuts, which can penetrate immediately and operate easily.

- Low odor type to reduce unpleasant odors at work

- Unique dual-purpose cap design, no need to replace nozzles

- Penetrating anti-rust lubricant can be sprayed upside down, making it easy to spray even in small areas

Anti-rust and lubrication performance tests under different environments:

| Soak: | Penetration test: 2.36mm/s |

| Anti-rust: | Salt water spray: 48 hours Indoor rust prevention: 6 months |

| lubricating: | Lubrication/reciprocating friction coefficient: 0.112 |

Product Usage:

- Anti-rust, lubrication and penetration of automobiles, motorcycles, bicycles and mechanical parts

internal volume:

- 420ml

Japan's original imported ICHINEN CHEMICALS CO., LTD. NX512 dry chain oil, water-resistant extreme pressure chain lubricant, is a white extreme pressure penetrating lubricating grease (with white solid lubricant), which has superior Water resistance and adhesion, lubrication and anti-rust effects are excellent.

feature of product:

- NX512 dry chain oil has penetrating properties and can penetrate into details

- NX512 dry chain oil, strong anti-corrosion, does not affect O-rings

- Excellent adhesion, minimal spatter, and excellent performance

- Excellent water resistance, acid resistance and alkali resistance, it can maintain its performance even if water splashes on its surface

- Good penetration spreads oil into every detail

- Because it contains white solid lubricant, it has extremely strong lubricity and can withstand pressure, and has good silencing effect during friction.

- Operating temperature range -15℃ to 120℃

- It is also possible to spray upside down, making it easy to spray even in small areas

internal volume:

- 300ml

Instructions:

- Shake your chain well before spraying it.

- Due to the low viscosity when sprayed, after spraying on high-speed rotating chains such as bicycle chains, they should be left for about 20 minutes.

- Clean the chain first if possible.

- 30-60 minutes after spraying, the lubrication will dry and show performance.

※Notice:

NX512 dry chain oil is flammable, please keep away from fire sources or high temperatures.

NX484 automotive repair anti-collision primer imported from ICHINEN CHEMICALS CO., LTD., Japan.

- Anti-collision primer with rubber-flexible granular coating

- Can be recoated with other paints after drying

- Excellent adhesion, water resistance, rust resistance and impact resistance

use:

Prevents scratches and damage to the car's front fenders, side skirts, door sills and other suspension devices caused by the impact of flying stones while driving.

| Technical data: |

| Drying time for 1 application (normal temperature) | Dry to touch: 20 minutes |

| Curing and drying: 1~2 hours | |

| Coating area | 1~1.5m 2 |

| Paint | Can |

color:

White

Internal capacity:

420ml

Showing 30/46