Sort by:

18 products

18 products

Rust removal, lubrication, and rust prevention can be completed in one go~

Japan Co., Ltd.'s イチネンケミカルズJIP130 ultra-durable anti-rust galvanized coating and Lubricating 303 anti-rust lubricating agent can prevent micro-degeneration and prevent rust from harming the human body and objects!

| Lubricating 303 anti-rust lubricating penetrating agent | |

| - | It can quickly penetrate the corroded metal surface and exert a lubricating effect on the rusted metal bottom layer. |

| - | Spray on rusted bolts and nuts, it can penetrate immediately and operate easily. |

| - | Low odor type to reduce unpleasant odors at work |

| - | Suitable for rust prevention, lubrication and penetration of automobiles, motorcycles, bicycles and mechanical parts |

| - | Capacity: 420ml |

| JIP130 super durable anti-rust galvanized coating | |

| - | Easily adsorbed on base metal, anti-rust and anti-corrosion |

| - | Can be used to protect metal surfaces even if they are scratched or damaged |

| - | Salt spray anti-rust test for 500 hours, good anti-rust effect |

| - | Suitable for oil drilling equipment, chemical industry, ship power equipment, car body manufacturing, storage tanks, bridges, harbor mechanical facilities, terminal equipment, railway equipment, buildings, vehicles, agricultural machinery, chemical instrumentation, etc. |

| rust removal brush | |

| - | A good helper for removing rust |

ICHINEN CHEMICALS CO., LTD. JIP130 ultra-durable rust-proof galvanized paint is a spray product made of single-liquid concentrated zinc and epoxy resin paint, which is anti-rust and super durable.

Concentrated galvanizing anti-rust agent anti-rust paint uses ultra-fine powdered metallic zinc to prevent iron corrosion in an electrically scientific and chemical manner. At the same time, a gradually stable insoluble protective film will be formed on the surface of the zinc powder, thereby increasing the anti-corrosion performance, even if the metal surface has been If there are scratches, you can also use this product to prevent rust and corrosion.

feature of product:

- Japan's ultra-durable anti-rust galvanized paint (concentrated galvanized anti-rust agent anti-rust paint, cold galvanized agent anti-rust spray paint)

- Super durable anti-rust galvanized paint, galvanized anti-rust paint, anti-rust and anti-corrosion

- Concentrated galvanizing anti-rust agent and anti-rust paint are easily adsorbed on the base metal

- Can be used to protect metal surfaces even if they are scratched or damaged

- Cold galvanizing agent anti-rust spray paint salt spray anti-rust test up to 500 hours, good anti-rust effect

- After the Japanese ultra-durable anti-rust galvanized coating is applied, any paint or coating can be applied. However, "phthalic acid" paint may cause delamination, so please do not use it.

Product specifications:

- Capacity 450g

- Color: silver gray

Performance/Characteristics::

- Metal powder in dry coating: 84% or more

- Soaked in tap water: more than 1 year

- Outdoor rust prevention: more than 2 years

- Drying time: Touch dry: About 5 minutes based on 20 degrees C / Curing and drying: 7 hours

- Salt spray anti-rust test: more than 500 hours (generally about 250 hours on the market)

- Film thickness: 15~25μm (this is the basis for one coating, and may vary depending on coating speed, distance, etc.)

- Coating area: 0.4~0.6m2 (calculated based on film thickness 30-40μm, there will be differences depending on the coating)

use:

- Cold galvanizing agent anti-rust spray paint is used for galvanizing repairs, primer anti-rust for welding parts, and anti-corrosion for steel pipes

- Suitable for oil drilling equipment, chemical industry, ship power equipment, car body manufacturing, storage tanks, bridges, harbor mechanical facilities, terminal equipment, railway equipment, buildings, vehicles, agricultural machinery, chemical instrumentation, etc.

Operating temperature range:

- Heat resistance ( short time ) : 180 ℃

- Heat resistance ( long time ) : below 150 ℃

ICHINEN CHEMICALS CO.,LTD. JIP694 super powerful rust remover is a metal rust remover and rust removal water . It is suitable for metal rust removal. It has good rust removal effect and can extend the use of components. longevity and ease of use.

feature of product:

- After soaking rusty metal or metal parts in JIP694 super powerful rust remover for a few minutes, the rust on the surface will fall off.

- Rust can be easily removed by just soaking, excellent rust removal effect

Product Usage:

- Suitable for rust removal on metals, not suitable for non-metallic materials and surfaces

- Suitable for removing oxidative films formed by concrete, lime, calcium deposits, etc. attached to metal surfaces

Instructions:

- After spraying evenly on the rusted area, let it sit for a few minutes.

- Wipe with a rag to remove rust.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, be sure to perform rust prevention treatment. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

How to deal with severe rust:

- Using a tool such as a steel brush, pour the rust remover onto the container, and then use the brush to brush the rusted surface.

- After applying the rust remover, it is necessary to allow the rust remover to take effect. The leaving time should not exceed 10 minutes, otherwise the rust removal reaction will cause normal parts to be corroded as well.

- Use a steel brush to remove rust spots on the surface.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, rust prevention treatment must be performed. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

Product specifications:

- Capacity 500ml

JIP695 immersion rust remover 4L comes with rust removal steel brush (DJ-0695-40004)

$4,675.00

Unit price perJIP695 immersion rust remover 4L comes with rust removal steel brush (DJ-0695-40004)

$4,675.00

Unit price perICHINEN CHEMICALS CO.,LTD. JIP695 immersion rust remover is a metal rust remover and rust removal water . It is suitable for metal rust removal. It has good rust removal effect and can extend the service life of components. and ease of use. It can also be used as a supplement to JIP694 super powerful rust remover .

feature of product:

- After soaking rusty metal or metal parts in JIP695 immersion rust remover for a few minutes, the rust on the surface will fall off.

- Rust can be easily removed by just soaking, and the rust removal effect is excellent.

Product Usage:

- Suitable for rust removal on metals, not suitable for non-metallic materials and surfaces.

- It is suitable for removing the oxidative film formed by concrete, lime, calcium deposits, etc. attached to the metal surface.

Instructions:

- After spraying evenly on the rusted area, let it sit for a few minutes.

- Wipe with a rag to remove rust.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, rust prevention treatment must be performed. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

How to deal with severe rust:

- Using a tool such as a steel brush, pour the rust remover onto the container, and then use the brush to brush the rusted surface.

- After applying the rust remover, it is necessary to allow the rust remover to take effect. The leaving time should not exceed 10 minutes, otherwise the rust removal reaction will cause normal parts to be corroded as well.

- Use a steel brush to remove rust spots on the surface.

- For long-term rust spots, treatment can be performed multiple times depending on the thickness of the rust spots.

- After rust removal, please clean the surface with water.

- After rust removal, rust prevention treatment must be performed. It can be used with JIP130 ultra-durable anti-rust galvanized paint for better results.

Product specifications:

- Capacity 4L

NX483 automotive repair and anti-collision primer imported from ICHINEN CHEMICALS CO., LTD., Japan.

- Anti-collision primer with rubber-flexible granular coating

- Can be recoated with other paints after drying

- Excellent adhesion, water resistance, rust resistance and impact resistance

use:

Prevents scratches and damage to the car's front fenders, side skirts, door sills and other suspension devices caused by the impact of flying stones while driving.

| Technical data: |

| Drying time for 1 application (normal temperature) | Dry to touch: 20 minutes |

| Curing and drying: 1~2 hours | |

| Coating area | 1~1.5m 2 |

| Paint | Can |

color:

black

Internal capacity:

420ml

NX482 automotive repair anti-collision primer imported from ICHINEN CHEMICALS CO., LTD., Japan.

- Anti-collision primer with rubber-flexible granular coating

- Can be recoated with other paints after drying

- Excellent adhesion, water resistance, rust resistance and impact resistance

use:

Prevents scratches and damage to the car's front fenders, side skirts, door sills and other suspension devices caused by the impact of flying stones while driving.

| Technical data: |

| Drying time for 1 application (normal temperature) | Dry to touch: 20 minutes |

| Curing and drying: 1~2 hours | |

| Coating area | 1~1.5m 2 |

| Paint | Can |

color:

grey

Internal capacity:

420ml

- JIP590 metal dye black pen, black repair paint in the form of correction pen

- The pen-type black dye can be easily repaired by drawing it on the peeling area.

- Forms a beautiful matte black film

- Uses special epoxy resin with excellent oil resistance

- Good fit and not easy to peel off when metal hits metal

Product Usage:

- Used to repair peeling parts of black dyed products

- Suitable for black coating of iron, aluminum, stainless steel, copper and other metals (cannot be used for plastic, rubber and other products)

Performance/Characteristics:

- Dry to the touch: 2~3 minutes

- Hardening and drying: about 20 minutes

- Heat-resistant temperature: 150℃ (continuous use 100℃)

- Coating area: 1.5-2m 2

- Operating temperature range: normal temperature

Product specifications:

- Content volume: 30ml

JIP179 metal blackening agent is a high-efficiency blackening colorant, specially designed for blackening various metal products or materials, such as iron, aluminum, stainless steel, copper and plastic. Originally imported from Japan's ICHINEN CHEMICALS CO., LTD., the black dye combines excellent performance and multi-functional features to ensure that your products achieve the best visual effects and protection.

Features:

Fast drying speed: JIP179 metal blackening agent has an extremely fast drying speed and maintains excellent adhesion, ensuring that the blackening effect is immediate.

Water Resistance: JIP179 metal black dye has excellent water resistance, ensuring your products maintain a long-lasting black coloration and are protected from moisture damage, even in humid environments.

Oil resistance: JIP179 metal blackening agent is not easily soluble in oil films and is suitable for applications that require contact with grease.

Wear resistance: This black dye shows excellent wear resistance and is not easily abraded or scratched. Even if metal collides with metal, it is not easy to peel off.

Ultra-thin coating: JIP179 metal blackening agent only forms an extremely thin film, maintaining the texture of the original material and does not affect the size or texture of the product.

Anti-rust function: This black dye also has anti-rust properties, ensuring that your metal products remain intact for a long time and extend their service life.

Low-gloss dark black: JIP179 metal black dye presents a low-gloss dark black, bringing a unique visual effect to your products, adding a sense of luxury and beauty.

In short, JIP179 metal blackening agent is a high-quality blackening product suitable for many application fields. It is an indispensable choice whether in industrial production, making exquisite handicrafts, or protecting metal surfaces from environmental influences. It brings a long-lasting black effect to your products while providing superior protection and visual beauty.

Be applicable:

- Black coating of iron, stainless steel, aluminum, copper and other metals

- Black coating of polyacetal resin (Polyacetal plastic steel) and ABS resin

- Partial repair of black products or small parts

Product performance:

- Dry to touch: 2 - 3 minutes

- Hardening and drying: about 20 minutes

- Heat-resistant temperature: 15℃ (continuous use 100℃)

- Coating area: 1.5m²

- Operating temperature range: normal temperature

Instructions:

- Before painting plastic, please test it to see if the plastic will be corroded.

- Thoroughly remove grease and clean the material to be dyed black before use

- Please shake well before spraying. When spraying, keep it about 20-30cm away from the object to be coated, and spray evenly. Please divide it into 2-3 times and spray it in batches. Do not spray it very thickly at one time to obtain the best blackening effect.

- The spray will dry within a few minutes, please proceed to the next step after it is fully dry.

Product specifications:

- 420ml

Origin:

- Made in Japan

※Notice:

JIP179 metal blackening agent is an ultra-fine particle blackening colorant, not a black spray paint~

It is flammable, please use it outdoors or in a place with good air circulation.

Please test whether the rubber spray will be corroded first.

Please stay away from fire sources or high temperature places.

- Japan's ICHINEN CHEMICALS company originally imported NX86 heat-resistant black heat-resistant paint heat-resistant paint, heat-resistant temperature 600 o C

- Heat-resistant black heat-resistant paint has less discoloration and will not peel off due to the thermal shock of cold water even at 600 ° C.

- High temperature resistant coatings can prevent corrosion such as salt damage

- Heat-resistant black heat-resistant paint When the heat-resistant paint film dries, it is heated to form a conformable hardened film.

- Imported from Japan

Product Usage:

- Used for steam pipes and other parts that require heat resistance

- Used in chimneys, boilers and other equipment

- Silencer box for generators, etc.

- Suitable for spraying of automobile and motorcycle exhaust pipes

Performance/Characteristics:

| Dry to the touch | 15~20 minutes |

| Harden and dry | Varies depending on heating conditions |

| heat resistance temperature | 600 ° C |

| Coating area | 0.6 ~ 0.7m 2 |

internal volume:

- 300ml

Remark:

- High-temperature resistant paint/heat-resistant paint generally refers to special functional paint that can withstand temperatures above 200 ° C for a long time and maintain certain physical and chemical properties so that the protected object can function normally in a high-temperature environment.

- Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD. original imported NX82 heat-resistant silver heat-resistant paint heat-resistant paint, heat-resistant temperature 600℃

- Heat-resistant silver heat-resistant paint has less discoloration and will not peel off due to the thermal shock of cold water even at 600 ° C.

- High temperature resistant coatings can prevent corrosion such as salt damage

- Heat-resistant silver thermal paint When the heat-resistant paint film dries, it is heated to form a conformable hardened film.

Product Usage:

- Used for steam pipes and other parts that require heat resistance

- Used in chimneys, boilers and other equipment

- Silencer box for generators etc.

- Suitable for spraying of automobile and motorcycle exhaust pipes

Performance/Characteristics:

| Dry to the touch | 15~20 minutes |

| Harden and dry | Varies depending on heating conditions |

| heat resistance temperature | 600 ° C |

| Coating area | 0.6 ~ 0.7m 2 |

internal volume:

- 300ml

Remark:

- High-temperature resistant paint/heat-resistant paint generally refers to special functional paint that can withstand temperatures above 200 ° C for a long time and maintain certain physical and chemical properties so that the protected object can function normally in a high-temperature environment.

KLIN WELD SE-F ethylbenzene-free welding groove rust inhibitor silver type (DJ-20355-42012)

$1,430.00

Unit price perKLIN WELD SE-F ethylbenzene-free welding groove rust inhibitor silver type (DJ-20355-42012)

$1,430.00

Unit price perWelding groove rust inhibitor:

Applied to all types of steel groove surfaces to avoid rust during welding.

Rust at the welding groove will lower the commercial value of the steel and cause various problems such as welding defects. From bevel processing to welding construction, using KLIN WELD SE-F bevel anti-rust agent can effectively solve these problems.

Generally, anti-rust agent is applied to the groove, and the anti-rust agent needs to be removed before welding. Using KLIN WELD SE-F groove anti-rust agent product, you can directly weld and reduce the operating procedures.

Product Features:

- Weld anti-rust, silver type

- Ethylbenzene-free type

- Can be directly welded

Performance/Characteristics:

- Coating: silver

- Dry to the touch: about 3 minutes

- Film thickness: 5-12µm

- Outdoor exposure test: 3-6 months

- Viscosity: 12±1 seconds (FC No.4)

- Coating area of 1L: 15-25m 2

capacity:

420ml

KLIN WELD YE welding groove rust inhibitor transparent type (DJ-20435-42012)

$1,470.00

Unit price perKLIN WELD YE welding groove rust inhibitor transparent type (DJ-20435-42012)

$1,470.00

Unit price perWelding groove rust inhibitor:

Applied to all types of steel groove surfaces to avoid rust during welding.

Rust at the welding groove will lower the commercial value of the steel and cause various problems such as welding defects. From bevel processing to welding construction, using KLIN WELD YE bevel anti-rust agent can effectively solve these problems.

Generally, anti-rust agent is applied to the groove, and the anti-rust agent needs to be removed before welding. Using KLIN WELD YE groove anti-rust agent product, you can directly weld and reduce the operating procedures.

Product Features:

- Can be directly welded

- Can be repainted

- The groove can be seen from above the coating film

Performance/Characteristics:

- Coating film: transparent

- Dry to the touch: about 20 minutes

- Film thickness: 5-7µm

- Exposure test: 1-2 months

- Viscosity: 11±1 seconds (FC No.4)

- Coating area of 1L: 15-25m 2

capacity:

420ml

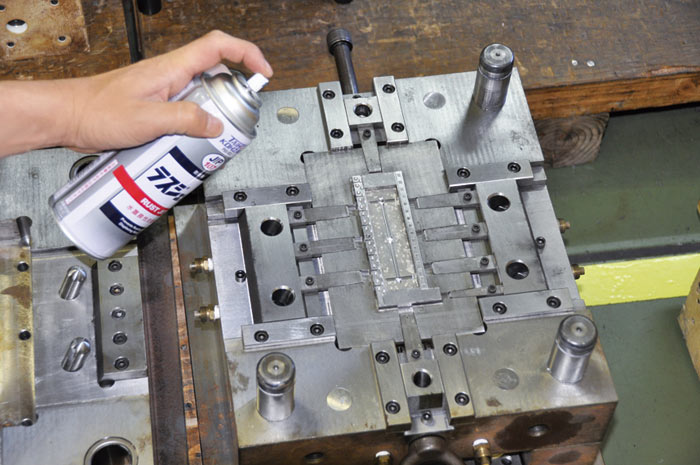

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml

JIP107 water-displacing anti-rust agent/anti-rust oil imported from Japan can effectively prevent any metal from rusting. It will not corrode the metal surface or cause discoloration. It can also prevent rust caused by fingerprints.

feature of product:

- Water displacing, suitable for preventing rust on any metal and will not corrode metal surfaces or cause discoloration

- Does not interfere with electrical contacts and has excellent protection for electrical equipment

- Prevents corrosion caused by seawater adhesion or working on the sea surface, and prevents rust caused by fingerprints.

- The skin of RUST JET can be easily removed using a topical remover.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Used for rust prevention of all metal products, precision machinery, jigs, plates, etc.

- Prevent complex cables such as electrical equipment, batteries, communication equipment, and motors from rusting

- Anti-rust treatment for metal molds

Performance/Characteristics:

- Salt water spray: more than 120 hours

- Indoor rust prevention: more than 24 months

- Outdoor rust prevention: not available

- Film thickness: 2~3µm

- Operating temperature range: -10~120℃

capacity:

420ml

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml

ICHINEN CHEMICALS CO., LTD. JIP130 ultra-durable rust-proof galvanized paint is a spray product made of single-liquid concentrated zinc and epoxy resin paint, which is anti-rust and super durable.

Concentrated galvanizing anti-rust agent anti-rust paint uses ultra-fine powdered metallic zinc to prevent iron corrosion in an electrically scientific and chemical manner. At the same time, a gradually stable insoluble protective film will be formed on the surface of the zinc powder, thereby increasing the anti-corrosion performance, even if the metal surface has been If there are scratches, you can also use this product to prevent rust and corrosion.

feature of product:

- Japan's ultra-durable anti-rust galvanized paint (concentrated galvanized anti-rust agent anti-rust paint, cold galvanized agent anti-rust spray paint)

- Super durable anti-rust galvanized paint, galvanized anti-rust paint, anti-rust and anti-corrosion

- Concentrated galvanizing anti-rust agent and anti-rust paint are easily adsorbed on the base metal

- Can be used to protect metal surfaces even if they are scratched or damaged

- Cold galvanizing agent anti-rust spray paint salt spray anti-rust test up to 500 hours, good anti-rust effect

- After the Japanese ultra-durable anti-rust galvanized coating is applied, any paint or coating can be applied. However, "phthalic acid" paint may cause delamination, so please do not use it.

Product specifications:

- Capacity 450g

- Color: silver gray

Performance/Characteristics::

- Metal powder in dry coating: 84% or more

- Soaked in tap water: more than 1 year

- Outdoor rust prevention: more than 2 years

- Drying time: Touch dry: About 5 minutes based on 20 degrees C / Curing and drying: 7 hours

- Salt spray anti-rust test: more than 500 hours (generally about 250 hours on the market)

- Film thickness: 15~25μm (this is the basis for one coating, and may vary depending on coating speed, distance, etc.)

- Coating area: 0.4~0.6m2 (calculated based on film thickness 30-40μm, there will be differences depending on the coating)

use:

- Cold galvanizing agent anti-rust spray paint is used for galvanizing repairs, primer anti-rust for welding parts, and anti-corrosion for steel pipes

- Suitable for oil drilling equipment, chemical industry, ship power equipment, car body manufacturing, storage tanks, bridges, harbor mechanical facilities, terminal equipment, railway equipment, buildings, vehicles, agricultural machinery, chemical instrumentation, etc.

Operating temperature range:

- Heat resistance ( short time ) : 180 ℃

- Heat resistance ( long time ) : below 150 ℃

NX484 automotive repair anti-collision primer imported from ICHINEN CHEMICALS CO., LTD., Japan.

- Anti-collision primer with rubber-flexible granular coating

- Can be recoated with other paints after drying

- Excellent adhesion, water resistance, rust resistance and impact resistance

use:

Prevents scratches and damage to the car's front fenders, side skirts, door sills and other suspension devices caused by the impact of flying stones while driving.

| Technical data: |

| Drying time for 1 application (normal temperature) | Dry to touch: 20 minutes |

| Curing and drying: 1~2 hours | |

| Coating area | 1~1.5m 2 |

| Paint | Can |

color:

White

Internal capacity:

420ml

JIP125 metal mold rust inhibitor is a liquid vaporized rust inhibitor, most suitable for rust protection of molds, precision machinery and various metals.

Product Features:

- Vaporizable, it can reach parts that cannot be directly sprayed by sprays, and can exert an anti-rust effect in subtle areas.

- After coating, an anti-rust film can be formed on the metal surface. The oxidized anti-rust molecules will absorb water molecules and convert them into anti-rust water, thereby preventing rust.

- Matched with metal molds, no cleaning required, effective after 2-3 sprays, shortening operation time

- It will not penetrate from the details of the metal mold and will not stain the finished product.

- Original imported from Japan Co., Ltd. ICHINEN CHEMICALS CO.,LTD.

Scope of application:

- Anti-rust agent, used for molds, various metal products and precision machinery (special for sealed anti-rust)

- Coating small metal parts with metal mold anti-rust agent and sealing them in plastic bags can prevent rust.

Performance/Characteristics:

- Completely sealed and rust-proof: 1-2 years

- Quasi-sealed rust prevention: half a year to 1 year

- Operating temperature range: below 80℃

capacity:

420ml